| A Quality Precision Mould Co., Ltd. | Branch Companies ❘ Taiwan ❘ Shanghai ❘ Tainjin ❘ Chongqing ❘ Zhongshan ❘ Xiamen ❘ Dongguan ❘ Wuhan |

| HOME | ABOUT US | FACILITIES | SERVICES | PRODUCTS | CONTACT US |

| Overview R&D Product Development Design Services Prototyping Tooling Services Molding Services Mold Components |

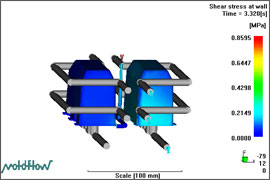

Design Services Much of our reputation for high quality stems from our experienced design staff. Molds are designed with an emphasis on efficiency and functionality up front which leads to time savings in production, longer lasting tools, and fewer modifications down the line. The foundation is set by our design team who experience designing injection molds of all shapes and sizes. AQM is committed to providing superior part design, mold design and engineering services. Design for manufacturability and efficient production is our primary objective. Early involvement and working closely with customer engineering departments provides a smooth transition from part design to final product. Every mold is designed in 3D, providing complete digital representations for manufacturing and ensuring proper integration of all components. Using a 3D model eliminates many of the traditional steps in the manufacturing process. Our integrated CAD/CAM system features the latest version of software running on 24 workstations, making paperless mold design and manufacturing possible. We are able to meet our customers' shortened lead times by giving our moldmakers a greater degree of control: they are able to access the model, interrogate it for dimensions, and begin machining electrodes and roughing out steel almost immediately. |

"Our goal is to help our customer reduce the overall cost of product procurement and enhance technical application, resulting in overall increased productivity and transactional efficiency." |

| Copyright 2010-2019 A Quality Precsision Mould Co., Ltd. All rights reserved. |

| Please feel free to contact us, just drop us a message or a call. | ||

| TEL: +86 769-8362-8799 | FAX:+86 769-8362-1380 | Email: ltd@aq-mould.com |

| Address: TianXin District, HuangJiang Town, DongGuan City, GuangDong Province, China. | ||